Sensors

-

LEDTECH LT9593-91-0125 PHOTO-TRANSISTOR

Ledtech # LT9593-91-0125 photo transistor. Water-clear T 1 3/4 with flat face.

-

OPTICAL SWITCH WITH INTERRUPT MECHANISIM

OPTICAL SWITCH WITH INTERRUPT MECHANISM Omron U-shaped opto-switch with a 0.2” gap. A spring-loaded plastic arm with a kind of flag at the end interrupts the switch beam. The arm slides back and forth through a teflon channel. Assembly mounted on a metal bracket, 2.32” x 1.1.”

-

VISHAY CNY65 OPTOCOUPLER - PHOTOTRANSISTOR OUTPUT

Vishay telefunken # CNY65. Optocoupler with phototransistor output in a 4-lead plastic package. Body size: 0.7" long x 0.37" x 0.24" high. PC pins. UL, VDE.

-

VISHAY SFH6106A-2 OPTOCOUPLER, PHOTOTRANSISTOR OUTPUT

Vishay SFH6106A-2 High-reliability optocoupler. Isolation test voltage: 5300 VRMS 4-pin DIP package. CTR 63-125% Note: These are blank unmarked (premarked) parts. Please call Ted at 514-739-8723.

-

SHARP YH9TM1 CCD module. In digital imaging and photography Charge Coupled Devices (CCDs) capture light on their surfaces which is converted into images. This CCD ais, in effect, a digital camera without a lens. We don't have documentation, but it's new and should be functional. Single pc board made for 3Com Corp. 1.2" x 0.65" x 0.34" thick.

-

SWITCHES, TOUCH BUTTONS,

LOGIC MODULES

AND MOREThis list contains a variety of electronic parts such as logic Modules, switches, touch buttons, and others manufactured by Banner Engineering. Click MORE INFO for details.

-

EXCESS INDUSTRIAL CONTROL PARTS

Modules, temperature controllers and more. Click on MORE INFO to see this listing of Barber-Coleman parts. Minimum order requirement may apply.

-

CHILLED FRESH WATER EXCHANGERS

PART NO. IM216.16American Standard, chilled fresh water exchangers,Manufacturer's part No. IM216.16, Shell test 150 PSIG, Tube test 100 PSIG. Tube length 14 in., Shell diameter 2.5 in.2 available.Both are in unused condition.

-

INDUSTRIAL HEAT EXCHANGER

COPPER-NICKEL ALLOY 90-10Shell and Tube Cooler, Material: 90-10 Cu-Ni Aqua Chem Model: WH-125ST, PN 738-7586, effective cooling surface of 18 sq ft. There are 39 u-tubes. The tubes are 3/8 OD, 0.049 wall and are made from 90-10 Cu-Ni in accordance with MIL-T-15005. Unit is unused and was designed for sea water in tubes and clean water in shell.Shipping Package Dimensions: 46in x 21in x 23in, Shipping Weight 300 lbs.Click MORE INFO for more photos in pdf format.

-

Turck 4MM Round Proximity Sensor 1.7m Pico QK Conn

o Part # 4623388 o BR-INR-AR7X-1.7m-PSG 3m w/mtg Screw

-

FLIR - High temperature option (+300°C to +1000°C) for FLIR E75

High temperature option (+300°C to +1000°C) for FLIR E75 Model# T199559 -> High temperature option -> +300 Degree C to +1000 Degree C -> For FLIR E75 -> For high temperature applications the camera can be calibrated for high temperature ranges.

-

FLIR - T199616 High-Temperature Option for T5xx Series Cameras, 572 to 2,192°F

FLIR High-Temperature Option for T5xx Series Cameras, 572 to 2,192°F Model# T199616 - Internal Upgrade for T5xx Series Thermal Imagers - Fits with T5xx Thermal Imager Cameras - Expands temperature range to +300°C to 1200°C (+572°F to 2192°F) - For high temperature applications the camera can be calibrated for high temperature ranges

-

• High Visibility Status Indication • Quick Installation • Standard Night Set Back • Audible Alarm • Multiple Mounting Options The Series AFA Siren™ Air Flow Alarm is an airflow monitor designed to provide visual and audible indications for decreases in airflow. Its color changing LED's provide vibrant visual indication of the operating status of the unit. A crisp and clear audible alarm will sound when airflow decreases below the designated set point. The Siren™ offers multiple mounting options including bracket mounting and interlocking strips. The unit can be powered through the 6-position terminal connection or by use of a power adapter. The Siren™ offers the ability to customize the minimum velocity set point should there be a need for a set point greater than the standard 80% of operational velocity. All units come standard with a night set back option for those who are energy conscious. The Siren also fulfills the exhaust alarm requirement needed to be in compliance with NSF/ANSI Standard 49. A quick installation process, one-touch calibration, and one-touch reset make for an easy set up and easy use.

-

SENSOCON Series VTP - Air Velocity Transmitter

The Series VTP Multi Range Air Velocity Transmitter can simultaneously display and output Air Velocity, Temperature and Pressure (optional). This is the first product to combine all 3 variables in one transmitter making the VTP an exceptional option for multi-variable measuring. The VTP utilizes an industrial 316 Stainless Steel armored RTD sensor as the thermal air velocity measuring component. Using a fully protected 316 SS sensor drastically extends the life of the air velocity sensor and also makes it insensitive to water, dust or corrosion. The VTP comes standard with a LCD and can simultaneously display air velocity, temperature, and pressure. The VTP is easily configured or adjusted in the field with the digital display and keypad. The Air Velocity Range and Pressure Range are both field adjustable as well as units of measure. Other adjustable parameters include signal dampening and low velocity cut off point. The VTP Air Velocity Transmitter can also be configured to measure and totalize flow in CFM or M3/h by entering the duct area where the measurement is taken. Installation of the VTP Air Velocity Transmitter is easy with the adjustable depth, removable flange. The standard product includes an integral design, but is also available with a remote mounted probe to accommodate any application.

-

SENSOCON Series JFM-P - FloSen® Airflow Probes

The Series JFM-P FloSen® Airflow Meassuring Probes provide accurate, repeatable measurement of air movement in HVAC ducts. Its patented elliptically-shaped sensor design with improved aerodynamic characteristics outperforms more traditional devices, and overcomes loss of accuracy caused by fluid separation at the sensor body. It is designed to maintain a constant parallel airflow pattern over the static sensing ports for more accurate, steady signals under all duct conditions. The elimination of separation results in a stabilized static pressure signal, helping to eliminate “hunting” during fan control. FloSen® Airflow Probes utilize a unique in-line groove for total pressure sensing and dual ports for static pressure sensing which produces a higher differential pressure for very low velocity measurements. The total and static pressure measuring points are distributed for equal-area averaging of flows resulting in improved accuracy and reliability. This design permits accurate and stable measurement in highly turbulent flow locations with directional pitch and yaw varying up to 20 degrees without the need for air flow straighteners which restrict airflow and can easily become clogged. The elliptical shape of the FloSen® Airflow Probes allows air to glide unrestricted around the aerodynamically designed sensors and offers the lowest pressure drop of any airflow measuring device available minimizing HVAC operating costs. The FloSen® Airflow Probes have been designed for easy installation and maintenance. The insertion-style probes can be completely installed from outside the duct. The quantity of FloSen® Airflow Measuring Probes selected for each duct size is based on ASHRAE and AMCA standards to produce assured airflow measuring accuracy over a flow turn-down ratio of 17:1.

-

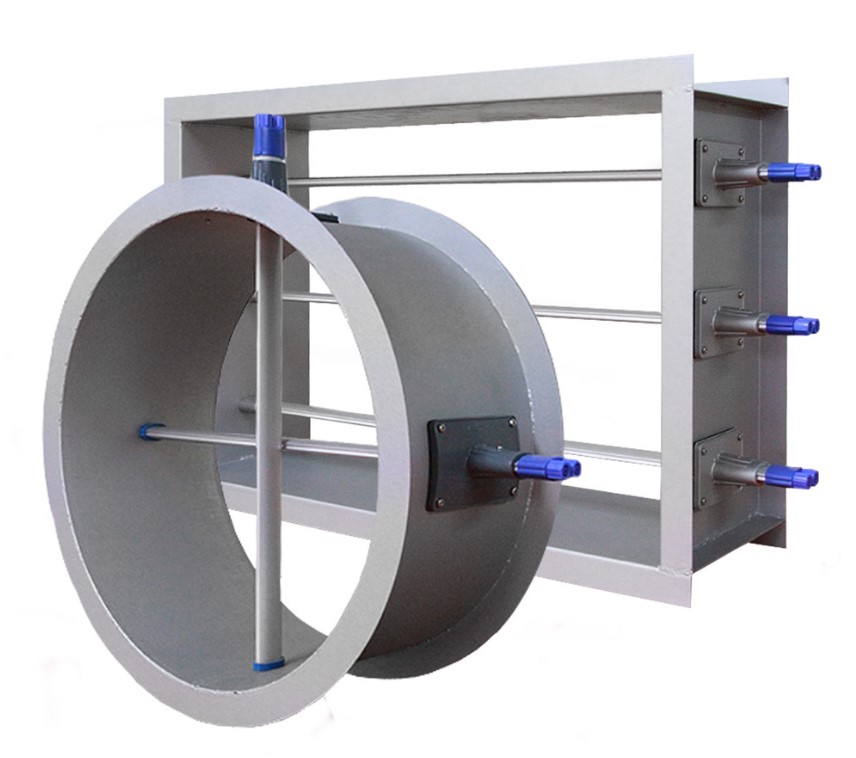

SENSOCON Series JFM-S - Airflow Station

The Series JFM-S FloSen® Airflow Measuring Stations provide accurate, repeatable measurement of air movement in HVAC ducts. The Probes patented ellipticallyshaped sensor design with improved aerodynamic characteristics outperforms more traditional devices, and overcomes loss of accuracy caused by fluid separation at the sensor body. It is designed to maintain a constant parallel airflow pattern over the static sensing ports for more accurate, steady signals under all duct conditions. The elimination of separation results in a stabilized static pressure signal, helping to eliminate “hunting” during fan control. Ellipse vs. Round The Elliptical Advantage Flow boundary layers attached to probe surface No separation effects No vacuum effects No vortex generation Low drag coefficient High repeatability Low static pressure signal affected by separation Vacuum effects limit turndown ratio to 4 to 1 Variable intensity vortices generateddownstream, creates signal amplifications, vibrations and acoustic problems High drag coefficient creates high pressure loss FloSen® Airflow Probes used in the Sensocon Airflow Measuring Stations utilize a unique in-line groove for total pressure sensing and dual ports for static pressure sensing which produces a higher differential pressure for very low velocity measurements. The total and static pressure measuring points are distributed for equal-area averaging of flows resulting in improved accuracy and reliability. This design permits accurate and stable measurement in highly turbulent flow locations with directional pitch and yaw varying up to 20 degrees without the need for air flow straighteners which restrict airflow and can easily become clogged. The elliptical shape of the FloSen® Airflow Probes allows air to glide unrestricted around the aerodynamically designed sensors and offers the lowest pressure drop of any airflow measuring device available minimizing HVAC operating costs. The JFM-S Airflow Measuring Stations have been designed for complete installation between ducts. The quantity of FloSen® Airflow Measuring Probes selected for each Flow Station is based on ASHRAE and AMCA standards to produce assured airflow measuring accuracy over a flow turn-down ratio of 17:1.

-

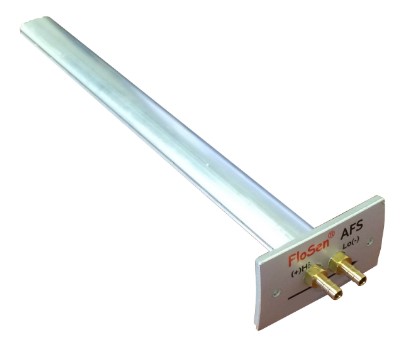

SENSOCON Series AFS Airflow Sensor

The Series AFS Air Flow Sensor is a differential pressure air velocity sensor designed to measure average air velocities in VAV terminal units and HVAC ductwork. It has an aero-dynamic elliptical shape resulting in a minimum pressure drop and amplified differential pressure signals which allow accurate measurement of air velocities from 300 fpm to 5000 fpm (1.5 m/s to 20 m/s). It includes multiple sensing points aligned in line grooves to measure total and static pressure. It is easy to install and cost effective. Series AFS Airflow Sensors are perfect for VAV Retrofits. The AFS is a differential pressure air velocity sensor designed to measure average air velocities in VAV terminal units and HVAC ductwork. The Series AFS Air Flow Sensor is a differential pressure air velocity sensor designed to measure average air velocities in VAV terminal units and HVAC ductwork. It has an aero-dynamic elliptical shape resulting in a minimum pressure drop and amplified differential pressure signals which allow accurate measurement of air velocities from 300 fpm to 5000 fpm (1.5 m/s to 20 m/s). It includes multiple sensing points aligned in line grooves to measure total and static pressure. It is easy to install and cost effective. Series AFS Airflow Sensors are perfect for VAV Retrofits. The AFS is a differential pressure air velocity sensor designed to measure average air velocities in VAV terminal units and HVAC ductwork.

866-266-7638

866-266-7638